Equatorial Launch Australia gears up for spaceport launches with the appointment of ex-RAAF Air Operations Officer and Airspace Control Team Lead, Joshua Daish, as the new Head of Arnhem Space Centre Site Operations

Spaceport operator and launch technology infrastructure company, Equatorial Launch Australia (ELA), today announced ex-Royal Australian Air Force Officer, Joshua Daish, as its new Head of Arnhem Space Centre Site Operations. Mr Daish will also take up the Launch Operations Manager role in ELA’s Launch Operations team.

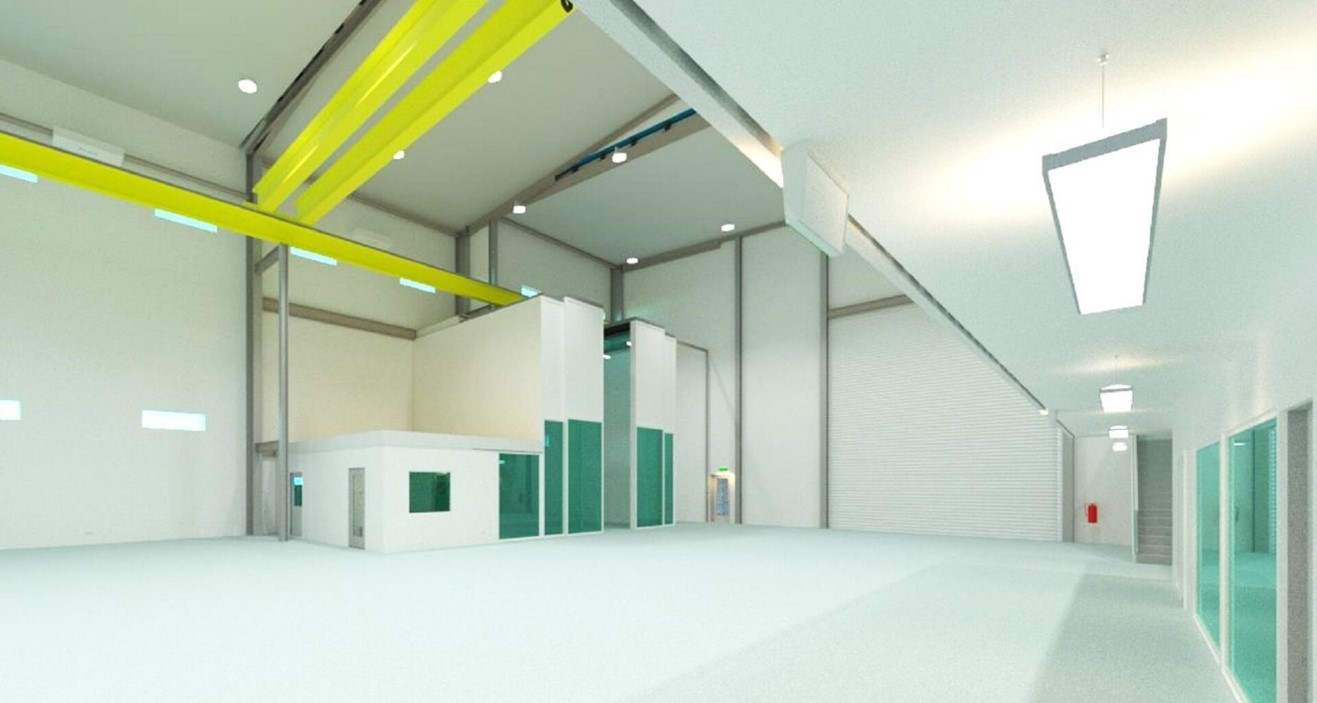

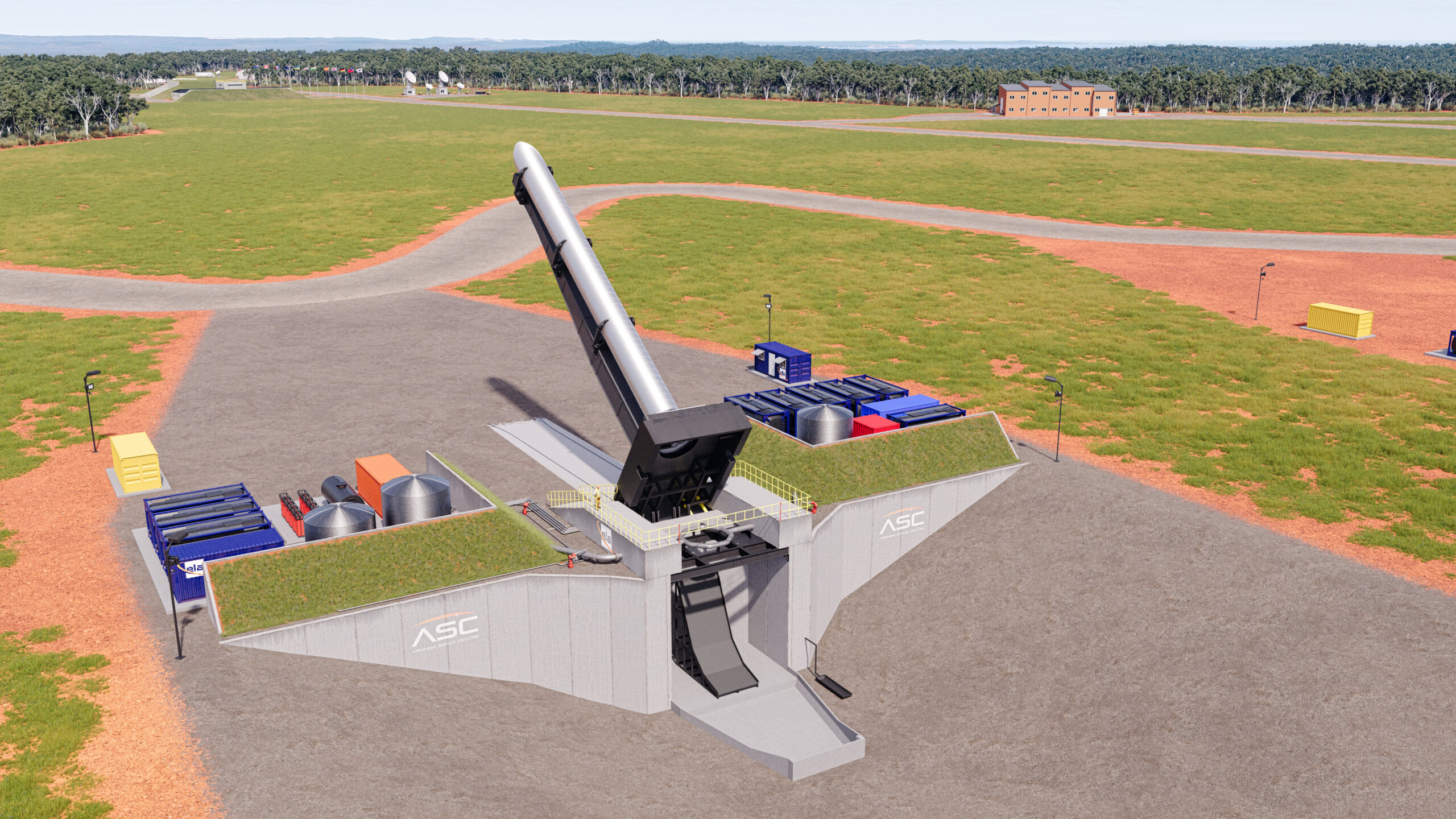

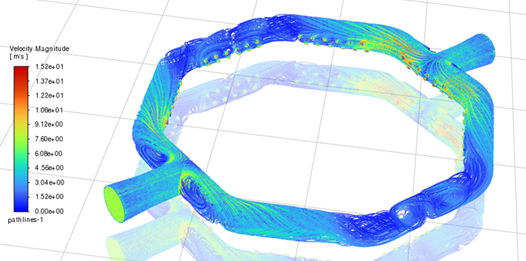

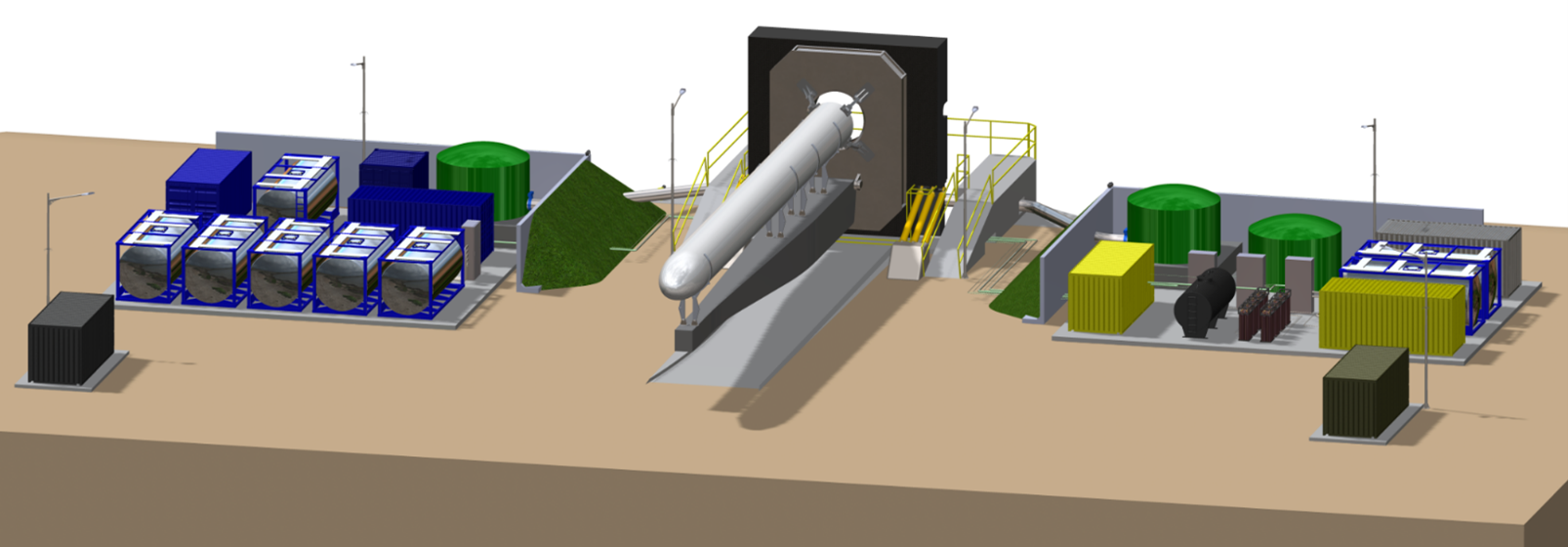

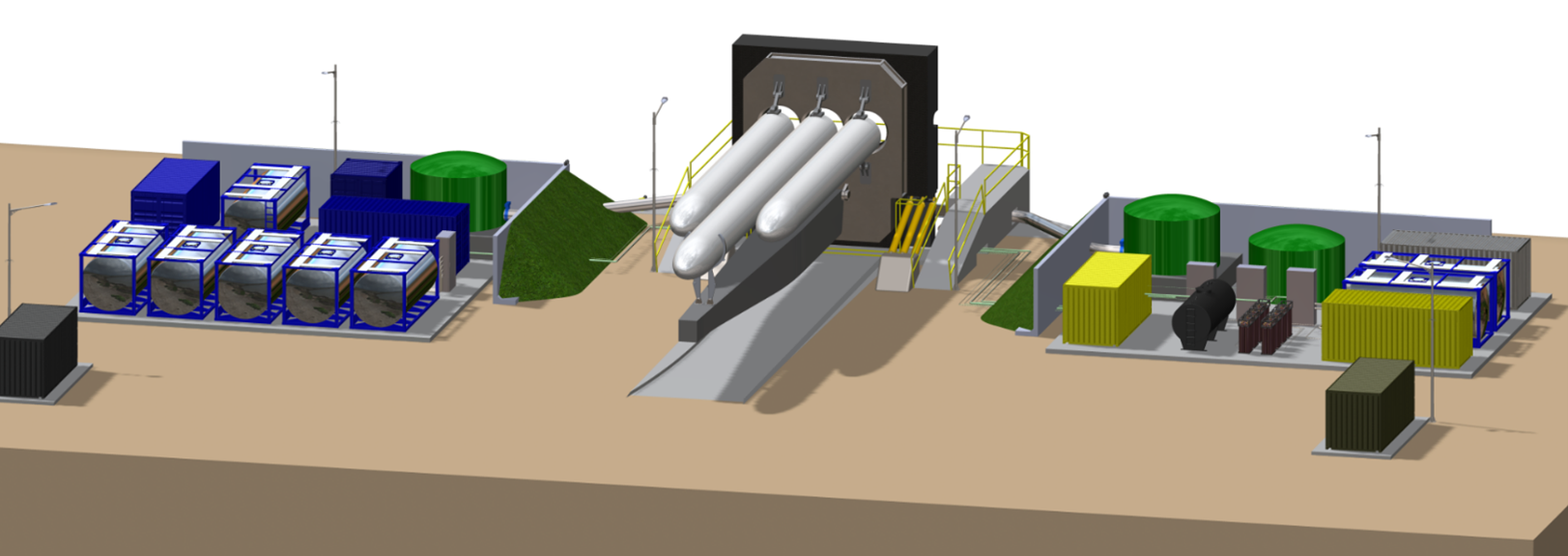

The recently established position will serve a critical role in the Phase Two redevelopment of ELA’s Arnhem Space Centre (ASC). Working closely with ELA’s CEO and within the leadership team, the role supports the company’s remit to further grow the spaceport into a world-class multi-user commercial launch facility. The new role will also be responsible for overseeing the development, preparation, and execution of spaceport activities in support of launch campaigns.

Group CEO of Equatorial Launch Australia, Michael Jones, welcomed Joshua by saying, “Joshua’s skills and knowledge of space, range and launch operations, as well as his 18 years of Royal Australian Air Force employment across multiple disciplines strengthens ELA’s executive talent by bringing additional operational aerospace expertise to the team as well as a deep understanding of space, aviation, safety management, and a broad technical base,’ he said.

“Josh is smart, hardworking and very talented and I am pleased to welcome him to the team. I am confident that his appointment will add considerable value to our customers and our staff as we move towards first launches from the redeveloped spaceport in 2025,’ said Mr Jones. “Josh will be integral in ensuring ELA lives up to our mantra of “You build the rockets; we’ll take care of the rest”.’

A key function of the role will be to act as a conduit between the ASC site support and operations team and ELA’s Launch Operations team and launch clients, while ensuring that the ASC’s facilities, equipment, and procedures allow for safe, effective and efficient launch activities.

With progress being made on the authorisation of the Technology Safeguards Agreement with the United States, as well as a growing groundswell of international interest in launching from the ASC, ELA is seeing a ‘turning of the tide’ as launch customers look to the company to help provide solutions to spaceport congestion overseas as well as key orbit options and mission and launch expertise.

“We’re experiencing a significant uptick in inbound enquiry for our services from the U.S., Europe and Asia,” said Mr Jones. “Our reputation as a world-leading spaceport with state-of-the-art facilities and our determination to provide seamless launch services for our customers is driving that interest. This is coupled with the fact that we are in deep discussions with multiple launchers to fill our remaining Space Launch Complexes – with launch companies realising they need to urgently secure a position at the ASC to guarantee their access.’

Mr Daish’s 18-year tenure with the RAAF has provided him with robust operational and leadership skills in highly technical and demanding aerospace environments, notably in Operations Management at Woomera Test Range Aerodrome which included supporting the return of JAXA’s Hayabusa 2 capsule and the first flight trials of BAE’s PHASA-35 and Boeing Defence Australia’s Loyal Wingman Uncrewed Combat Aircraft.

Mr Daish cited ELA’s strong focus on cutting-edge space launch technology and its approach to developing a spaceport that works seamlessly with customer mission objectives as some of the primary reasons for his move into the sector. “I have always had a keen interest in space even from a very young age; being able to play a critical role in the development and conduct of space activities within an Australian company such is ELA was a very attractive prospect,’ he said.

He will split his time between ELA’s headquarters in Adelaide’s CBD with extensive travel to the Arnhem Space Centre in East Arnhem Land.

ELA is well on track to be the pre-eminent multi-user commercial space launch company providing testing, launch and recovery of space vehicles and payloads flown to and from all space orbits. The newly crowned ‘Launch Business of the Year’ in the AusSpace24 Australian Space Awards, ELA owns and operates the Arnhem Space Centre, which is located in Australia’s Northern Territory, at 12o south of the equator – offering rocket companies and their payload customers multiple orbit options, operational freedom and simplicity for their launch and mission design.